A Highly Efficient Domain Decomposition Method Applied to 3-D Finite Element Analysis of a Switched Reluctance Motor

Wang Yao with advisers J. M. Jin and P. T. Krein

An ideal computer-aided design tool (CAD) for electric machines could (1) model the complex geometry and various material properties of a machine and (2) provide accurate results in a reasonable amount of time. Popular CAD tools, including finite element analysis (FEA) compromise on one of these two requirements. FEA can yield an accurate prediction of machine performance but simulations require massive computational effort, especially for three-dimensional (3-D) problems. Problems with several million unknowns are common in a 3-D simulation and are challenging to solve quickly. In this report, a highly efficient domain decomposition method, the dual-primal finite element tearing and interconnecting (FETI-DP) method, is adopted, together with parallel computing schemes, to expand the capability and improve the efficiency of 3-D FEA. The FETI-DP method divides an original large-scale problem into smaller subdomain problems and then handles the subdomains in parallel using multiple processors to significantly reduce the total computation time. Computationally efficient methods ultimately lead to tools for design and optimization.

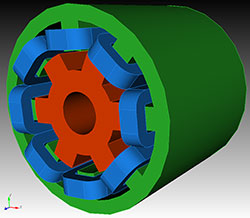

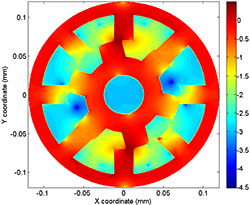

To validate our algorithm and demonstrate its performance, we simulate a switched reluctance motor (SRM). The SRM can operate at high speeds. Our simulated SRM has eight stator poles and six rotor poles. The 3-D motor configuration is shown in Figure 7. Coils are wound to best utilize the interpointerpolar space. Each phase consists of two coils, wound around two opposite stator poles and connected in series. Conventionally, the phases are individually excited in sequence. The magnetic material is assumed to be linear. The magnitude of magnetic flux at the z = 0 plane is plotted on a logarithmic scale in Figure 8. For FETI-DP simulations, the total number of unknowns is 3,111,026. With 128 processors, the whole simulation process takes only 85.72 seconds. Thus, 3-D FEA efficiency is significantly improved by using the proposed algorithm. This research is supported by the Grainger Center for Electric Machinery and Electromechanics.

This work is funded by the Grainger Center for Electric Machinery and Electromechanics

and the University of Illinois SURGE Fellowship.