Design Strategies for Inverter-Controlled Induction Machines

Matthew Magill with Adviser P.T. Krein

Common machine configurations for both synchronous and asynchronous systems utilize an integral number of stator slots (Ns) per phase. Although the number of stator slots per pole per phase can be fractional, the requirement for equal winding patterns in each phase, and hence equal voltage generation, creates a design restriction on machine laminations. There is rarely a clear-cut choice for Ns in a particular application. When selecting the number of rotor conductors in a cage-rotor induction machine (Nr), there are innumerable possilbilies. This project studies the impact of slot combinations within inverter-controlled settings by adapting previous work focused on determining ideal Ns/Nr combinations for line-fed induction machines.

Common machine configurations for both synchronous and asynchronous systems utilize an integral number of stator slots (Ns) per phase. Although the number of stator slots per pole per phase can be fractional, the requirement for equal winding patterns in each phase, and hence equal voltage generation, creates a design restriction on machine laminations. There is rarely a clear-cut choice for Ns in a particular application. When selecting the number of rotor conductors in a cage-rotor induction machine (Nr), there are innumerable possilbilies. This project studies the impact of slot combinations within inverter-controlled settings by adapting previous work focused on determining ideal Ns/Nr combinations for line-fed induction machines.

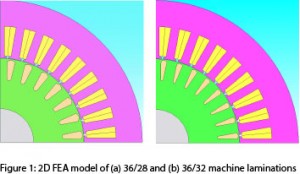

Field-based analyses of slot combination consequences on magnetic noise, radial forces, parasitic torques, and harmonic losses have been previously carried out in great detail for machines for fixed supply frequencies. The effects of each of these performance metrics throughout the traditional torque/speed profile have led to design tradeoffs used to create empirically-derived slot combination tales. Our goal is to show possible performance benefits of previously rejected lamination topologies when they are operated with a variable frequencey supply. Favorable results would open up the design space for cage-rotor induction machines and allow for additional design arrangements. Introductory studies have involved finite element magnet modeling of small-to-medium sized induction machines similar to those seen in Figure 1. This research is supported by the Grainger Center for Electric Mahcinery and Electromechanics.

This work is funded by the Grainger Center for Electric Machinery and Electromechanics and the University of Illinois SURGE Fellowship.