Design and Modeling of Hybrid Power Systems for Mobile Refrigeration in Delivering Truck Applications

Yue Cao with adviser P. T. Krein

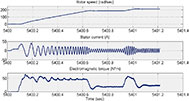

Figure 13: Dynamic response of rotor speed, stator current, and electromagnetic torque during compressor start up

This industry-based project develops a hybrid power system model for mobile refrigeration applications to be used by the R & D team at Ingersoll Rand/Thermo King. The engine-powered system works as follows: an engine shaft drives an ac generator feeding an ac-dc rectifier, to a stabilized dc bus, then through a dc-dc converter, a dc-ac inverter, and eventually to an ac induction machine driving the compressor. A battery-powered system is in parallel and joins the engine-powered system at the dc bus. The battery model comprises various nonlinear parameters, such as state of charge, transient resistors and capacitors that, together, simulate battery pack dynamics. The objective of the hybrid system modeling is to analyze dynamic response, practicality, efficiency, and fuel cost.

The hybrid power system model is built in a Matlab/Simulink environment. A detailed circuit model is designed to simulate the dynamics in all the electric components. Figure 13 illustrates the dynamic response of rotor speed, stator current, and electromagnetic torque during compressor start up. Another average mathematical model is created to simulate system-level power variation and efficiency at a much faster simulation speed. Figure 14 shows efficiencies of various components for a wide range of period, including engine running and battery power. Future work will consist of experimental validation of the system and more energy optimization study with advanced control and automation. This research is supported by Ingersoll Rand/Thermo King.

This research is supported by the Grainger Center for Electric Machinery and Electromechanics.