A magnetic sensing approach to characterize corrosion in reinforced concrete

Melanie Johnson with adviser Patrick L. Chapman

Corrosion damage to reinforcing steel plagues civil infrastructure in the United States and causes an estimated $6 to 10 billion of damage per year to bridge decks alone. Despite this cost, no reliable non-destructive testing method exists to detect the presence of corrosion or the rate at which corrosion occurs. Existing methods, such as visual inspection and half-cell potential measurements, are unable to fully characterize damage. The goal of this project is to develop a new sensing technique based on magnetic field measurements that will accurately measure both the state and rate of corrosion in reinforcing steel.

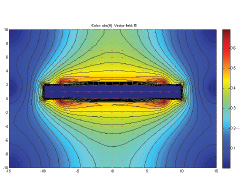

Working jointly with a group in the Civil Engineering Department, the project seeks to employ giant magneto-resistive (GMR) sensors to measure the small magnetic field generated by electric currents caused by corrosion. Recent work focuses on identifying the sensitivity and range of the GMR sensors. This task requires the external field of a solenoid to be determined using a variety of methods including direct analytical calculation and two- and three-dimensional finite element analysis modeling. These results allow the theoretical magnetic field intensity to be compared with the measured value given by the GMR sensor. Figure 27 is a model of a solenoid’s magnetic field produced by two-dimensional FE analysis. Other GMR sensor tests include measuring the magnetic field of rebar specimens placed in acid and tap water. The sensors will also be tested on rebar with an epoxy coating in specific regions to cause localized corrosion in uncoated areas. The data from these tests will be analyzed for patterns in the magnetic field that indicate the presence of corrosion.

This project is supported through the National Science Foundation Grant, Development of Sensing Methods for Complete In Situ Assessment of Steel Corrosion in Concrete, NSF CMS 06-25996.