Improving Efficiency, Performance, and Reliability of Solar Photovoltaics using Differential Power Processing

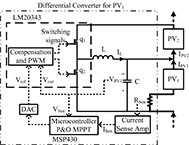

Figure 16(b): A diagram of the components contained in one sub-panel differential converter prototype.

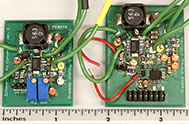

Figure 16(a): Hardware prototypes of a sub-panel converter.

Pradeep Shenoy with adviser P. T. Krein

This research develops a new paradigm in energy conversion for solar photovoltaics (PV). PV installations try to produce as much energy as possible over the life of the system to be more cost effective. Unfortunately, conventional energy conversion architectures are forced to make a tradeoff between maximum power production and overall energy conversion efficiency. This is primarily due to the mismatch in maximum power point (MPP) current of series PV elements. To overcome this limitation, differential power processing has been introduced to reduce the amount of energy that is processed by the energy conversion circuits. A small difference in current is injected into intermediate nodes to enable each series PV element to independently operate at its local MPP. Since differential converters are processing only a small fraction of the total power, overall energy conversion efficiency is very high.

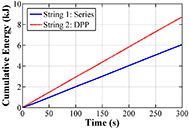

Figure 17(a): The measured energy generated by two series PV strings with and without differential power processing under 5% partial shaded conditions.

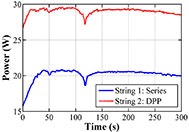

Figure 17(b): The measured power generated by two series PV strings with and without differential power processing under 5% partial shaded conditions.

Local information can be used by differential converters to track the MPP. The diagram and photograph of sub-panel hardware prototypes are shown in Figure 16. A microcontroller can use PV current and voltage measurements to determine the optimal reference voltage for the differential converter. Experimental results shown in Figure 17 for a 5% shading condition demonstrate that almost 50% more power and energy can be generated using a differential converter as compared to the conventional series PV string approach. Protection and monitoring capabilities add value to locally controlled differential converters. Global MPP tracking in a central inverter is simplified because local minima (the kinks in the current-voltage curve) can be eliminated. Overall energy generation is increased. As differential converters process minimal power, there is potential to integrate these systems in small packages or on-chip for high volume, low cost production. Differential power processing has the potential to substantially improve the levelized cost of PV systems energy. This work was supported by the Grainger Center for Electric Machinery and Electromechanics and Advanced Research Projects Agency-Energy (ARPA-E), U.S. Department of Energy, under Award Number DE-AR0000217.

This research is funded by the Grainger Center for Electric Machinery and Electromechanics.