Dithering Digital Ripple Correlation Control for Photovoltaic Maximum Power Point Tracking

Christopher Barth with adviser R. C. N. Pilawa-Podgurski

This project is developing a new maximum power point tracking algorithm for use in switching power converters for PV applications. To maximize energy harvested from a PV panel, it is necessary to operate the panel at a particular current and voltage value, the panel maximum power point. The MPP changes with solar conditions, temperature, and panel age, necessitating continuous tracking.

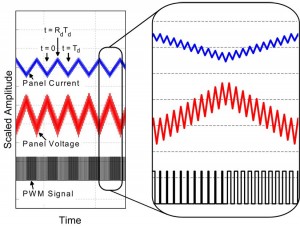

Dithering digital ripple correlation control (DDRCC) employs pulse width modulation (PWM) dithering to, first, increase the control resolution of the solar power converter hardware and, then, perform MPP tracking using the ripple created by dithering. Figure 14 shows the ripple which occurs in panel voltage and current as the converter is dithering between duty ratios. Panel current and voltage are sampled at t = 0 and t = RdTd, corresponding to the beginning and end of the high-duty ratio period. If the power measurements at t = 0 and t = RdTd are identical, the converter is operating the PV panel at the maximum power point. If the power measurements differ, the sign of the difference in power indicates the required converter duty-ratio change.

Results published in June 2013 demonstrated the high tracking capability of DDRCC at low power levels. New hardware shown in Fig. 15 has been constructed to incorporate a windowed measurement technique for high resolution current and voltage measurements over a range of power levels. Preliminary results have been obtained. Current work is focused on refining the hardware to improve MPP tracking ability for single-panel applications such as off-grid battery charging.

This research is funded by the Illinois Center for a Smarter Electric Grid.